propane Installation guidelines

Fire Marshal approval is required before you move or install a propane tank. To gain this approval, please follow all of the steps listed below:

Plans are reviewed and processed during normal business hours Monday-Friday. Approximate time for reviewing plans is 7-14 business days.

Please complete the Propane Inspection Checklist to ensure that you meet all requirements. This form is meant to be used as a job aid to help ensure compliance will be met at the time of inspection.

Complete the Project Application Form using the button above.

To schedule your rough & final propane inspection, use the button at the top of this page. You will be redirected to the booking page where you can schedule your inspection.

UNDERGROUND TANKS

Underground LPG tanks are inspected, and approved by the local Fire District having jurisdiction prior to building final.

TRENCHING

-

• The minimum cover shall be shall not be less than 12”. Where external damage to the pipe from external forces is likely to damage pipe cover shall not be less than 18”.

-

• Field applied wrapping shall be limited to short sections which have been stripped for threading purposes and field joints. Spirally wrap as listed, minimum 10 millimeter tape to a 40 millimeter thickness 6” inches beyond the joints.

-

• Underground plastic piping must have a tracer wire (minimum 14 AWG) or tape for its full length, one end shall be brought above ground at building wall or riser. Plastic pipe may terminate above ground where an anodeless riser is used.

TESTING

Test pressure to be used shall be a minimum of 10 psi for 15 minutes. For piping carrying gas pressures in excess of 14 inches water column pressure, test pressure shall be not be less than 60 psi for 30 minutes.

RESOURCES

PROPANE INSTALLATION INSPECTION CHECK SHEET

PLACER COUNTY PROPANE INSTALLATION GUIDELINES

INFORMATION BULLETIN ON PROPANE/LIQUID PETROLEUM GAS TANK INSTALLATION

GUIDELINES FOR PROPER PROPANE TANK INSTALLATION FOR HIGH COUNTRY SYSTEMS

STRUCTURES OVER PROPANE TANKS

METER SHELTER 800 PSF 7-2023

SOUTHWEST GAS: HOME & BUSINESS SAFETY (swgas.com)

LIQUID PROPANE GAS TANK INSTALLATION

-

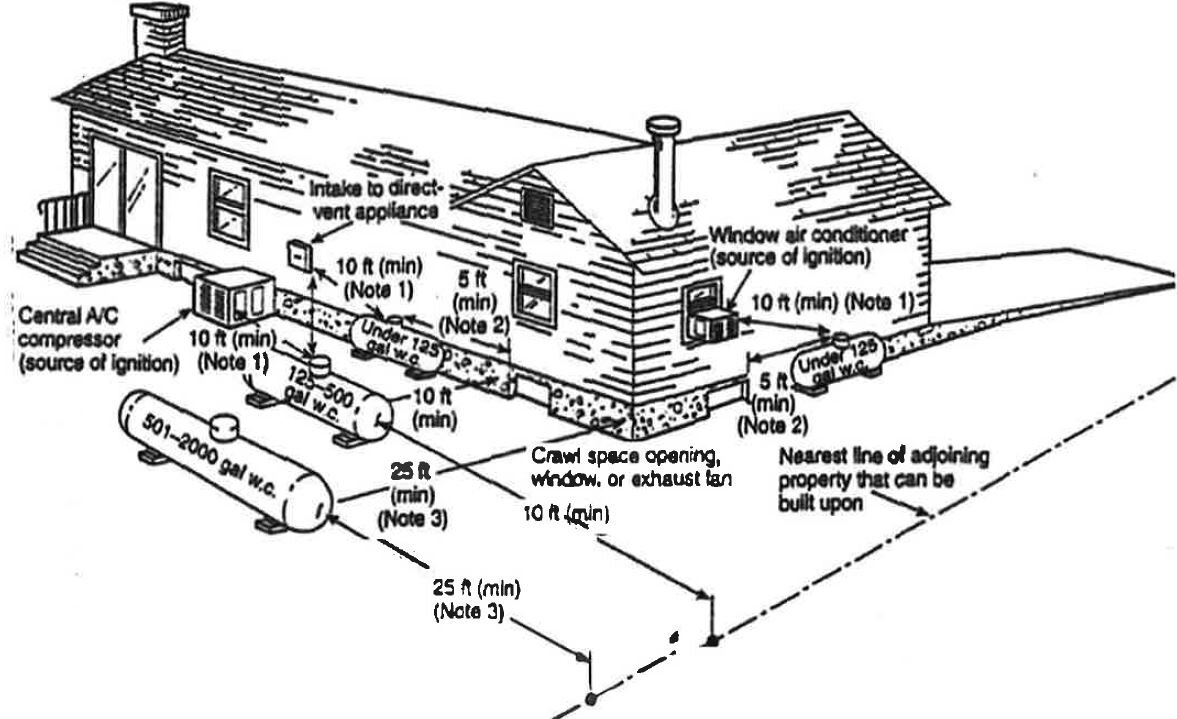

• Regardless of its size, any ASME tank filled on-site must be located such that the filling connection and fixed liquid level gauge are at least 10’ from any external source of ignition (ie: electrical service, open flame, furnace, A/C compressor, etc.) intake to a direct vented gas appliance or intake to a mechanical ventilation system.

• A single tank not exceeding 1,200 gallons may be 10’ from buildings and property lines provided there are no other tanks within 25’.

-

• For installations above 5000’ elevation installation shall be as prescribed by the local Fire District. Click HERE to review a typical aboveground tank in areas of heavy snowfall.

-

• Tanks up to 125 gallons shall be at least 5’ from buildings and property lines. Tanks of this size may be located adjacent to the building it serves under certain conditions as shown in the detail.

-

• Tanks of 126 to 500 gallons shall be at least 10’ from buildings and property lines.

-

• Tanks of 501 to 2000 gallons shall be at least 25’ from buildings and property lines.

INSTALLATION OF EXTERIOR GAS PIPING MATERIAL

-

Gas piping which is above grade may be wrought iron, steel (black or galvanized) yellow brass or internally tinned copper.

Underground gas piping may be plastic (PE) rated for use with gas, or factory coated steel pipe.

Gas piping must be new or previously used for gas only.

-

Section 605.9 Gas Meters, as amended in the Truckee Fire Protection District Ordinance 01-2022 requires:

Regulators and piping subject to damage shall be protected

New meters must be installed at the gable end of a building

A protective cover to support snow load and installed over the meter assembly

Meters shall be protected from snow or ice where located underground piping extends above ground